| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : EVERSUN

Model Number : ZKJ

Certification : ISO,CE

Place of Origin : CHINA

MOQ : 1set

Price : negotiable

Payment Terms : L/C, D/A, D/P, T/T, MoneyGram, Western Union

Supply Ability : 5000set/year

Delivery Time : within 7-15 work days

Packaging Details : Standard export wooden cases

Application : Material Handling

Function : Conveying material

Cleaning Method : Automatic

Quality : GMP Standard, ISO and CE certified

Warranty : 1 Year

Diameter : Customizable

Vacuum Source : Vacuum pump, Roots fan

Noise : ≤65dB

Vacuum Level : Adjustable

Product description

The intermittent vacuum feeder is an automated equipment that conveys materials through vacuum suction force. Its structure is compact and operation is convenient. It adopts a closed conveying design, which can effectively prevent dust from spilling out during the transmission of materials, meeting the strict requirements of clean production in the food, chemical, pharmaceutical and other industries. This equipment is suitable for the transportation of powdery and granular materials. It can flexibly transfer materials at different heights and distances, and can be seamlessly connected with other production equipment, significantly improving production efficiency and greatly reducing the labor intensity of workers. It is an ideal choice for the modern industrial material transportation process.

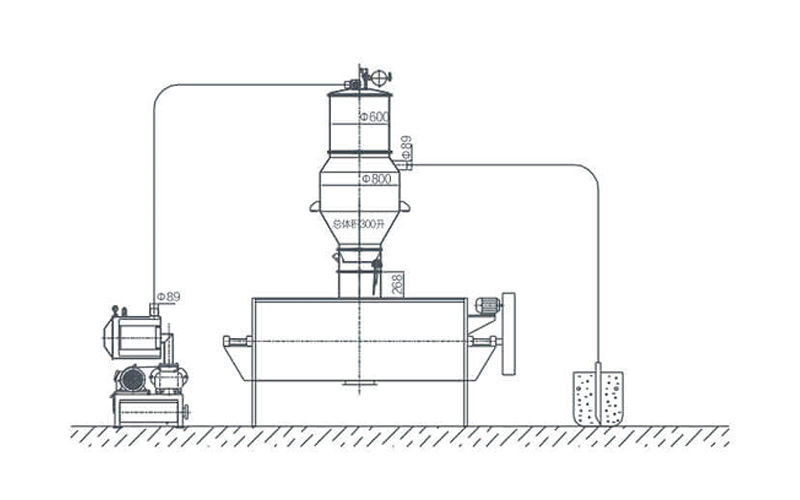

Working principle

The working principle of the intermittent vacuum feeder is to use a vacuum pump to generate vacuum suction force to achieve material transportation. After the equipment is started, the vacuum pump operates to create a vacuum environment in the pipeline and the silo. The material at the feeding port is pressed into the pipeline under the action of atmospheric pressure and then sucked into the storage silo along the pipeline. When the material in the storage bin reaches the set feeding amount, the vacuum system stops working. Under the action of gravity or other discharge devices, the material is discharged through the discharge port, completing one material conveying cycle. Through such intermittent working mode, quantitative and efficient material transportation can be achieved.

Product features

High-efficiency conveying: By using vacuum suction to convey materials, it can quickly transfer materials from one place to another. Especially for powdery and granular materials, the conveying efficiency is high, which can effectively improve production efficiency.

Clean and environmentally friendly: It adopts a fully enclosed conveying method, which avoids dust flying during the conveying process of materials, reduces environmental pollution, and also ensures the cleanliness and hygiene of the production environment, meeting the hygiene requirements of the food, pharmaceutical and other industries.

Easy operation: The operation of the equipment is relatively simple. Usually, only relevant parameters such as vacuum degree and feeding quantity need to be set, and automatic feeding can be achieved without a large amount of manual intervention, reducing the labor intensity of workers.

High flexibility: It can flexibly adjust the conveying distance and height according to different production needs, and can be conveniently connected with other production equipment to meet the requirements of various production processes.

Strong material adaptability: It can convey various powdered and granular materials, such as flour, sugar powder, pharmaceutical granules, chemical raw materials, etc., very well, and has a wide range of applications.

Low maintenance cost: The structure of the equipment is relatively simple, mainly composed of vacuum pumps, storage bins, pipelines and other components. The maintenance and care of these components are relatively convenient, and they are less likely to malfunction, reducing maintenance costs and downtime.

| Model | Hopper Capacity(L) | Working pressure | Conveying Capacity(kg/h) | Compressed air consumption |

| QVC-1 | 1.1 | 0.4-0.6Mpa | 50-300 | 180NL/min |

| QVC-2 | 6 | 0.4-0.6Mpa | 100-700 | 360NL/min |

| QVC-3 | 12 | 0.4-0.6Mpa | 300-1500 | 720NL/min |

| QVC-4 | 42 | 0.4-0.6Mpa | 600-3000 | 1440NL/min |

| QVC-5 | 60 | 0.4-0.6Mpa | 900-6000 | 2880NL/min |

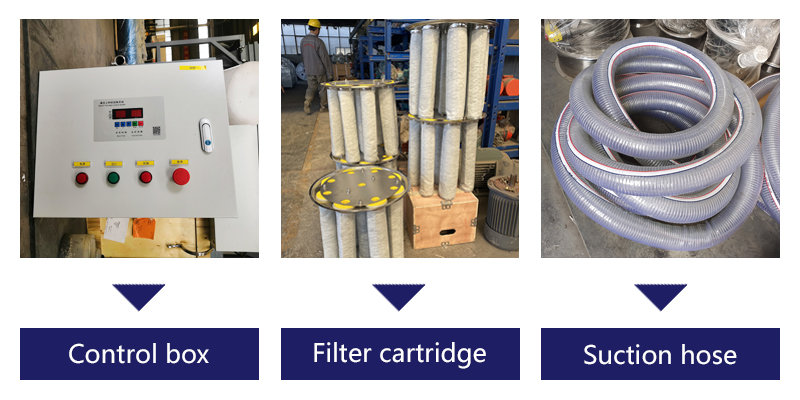

Product details

Product shows

Application

Wide range of applications: The vacuum loader is mainly used for conveying powdery and granular materials, such as raw pharmaceutical powders,

chemicalders, metal oxide powders, etc.; however, it is not suitable for conveying overly moist, sticky, or heavy materials.

Packaging & Shipping

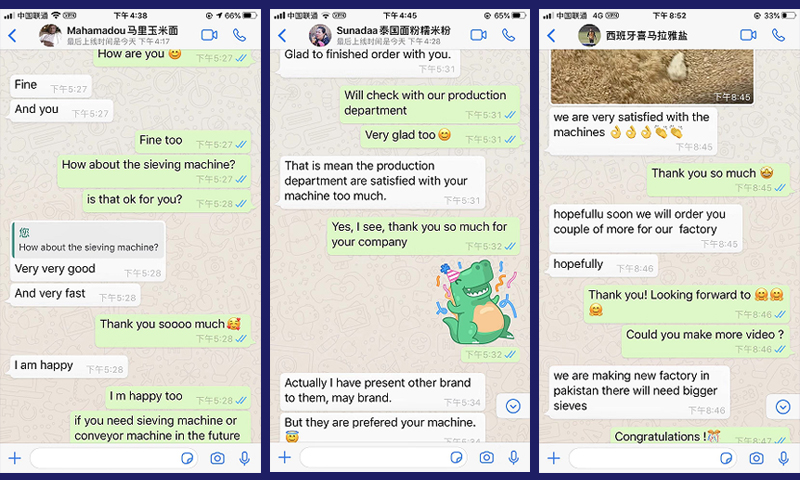

Why Choose us

About us

We have been specializing in the production of Screening and conveying equipment for 13 years. China's vibrating screen industry top three. And we have done matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are often exported to Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will arrange everything for you. Our factory address: West of the industrial and commercial office of Da Zhaoying Town, Xinxiang City, Henan Province.

|

|

High Throughput and Hygiene Standards Vacuum Conveyor Systems for Food Pharmaceutical and Chemical Factories Images |