| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : EVERSUN

Model Number : V

Certification : ISO,CE

Place of Origin : CHINA

MOQ : 1set

Price : negotiable

Payment Terms : L/C,D/A,D/P,T/T,MoneyGram,Western Union

Supply Ability : 5000set/year

Delivery Time : within 7-15 work days

Packaging Details : Standard export wooden cases

Volume : 50L-5000L

Function : Mixer Blender

Weight : 120-2300kg

Application : Mixing dry powder materials

Driving Type : Electric

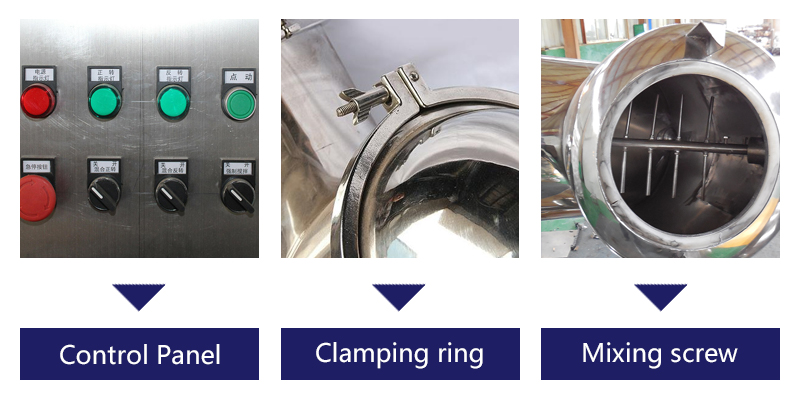

Features : V-shaped container, double helix mixing blades, adjustable mixing speed

Noise : ≤80dB

Dynamic Type : Electric

Product Type : powder and granules

Dimension : Customizable

Material : Stainless Steel

Power Supply : 220V/380V

Model : V Type Powder Mixer

Warranty : 1 year

Application Areas : Various industries

Customization : Available upon request

V-Type Mixer

Product Description

The V-shaped mixer is a commonly used powder mixing equipment in the food and chemical industries. Its core component is the symmetrical V-shaped cylinder. By rotating the cylinder asymmetrically, the material can achieve uniform mixing within the cylinder. The inner wall is smooth without any dead corners and is easy to clean, meeting hygiene standards and preventing cross-contamination. It is suitable for dry powder mixing requirements.

Working Principle

The working principle of the V-shaped mixer is that the V-shaped cylinder body rotates asymmetrically around the central axis, causing the powder inside the cylinder to first rise along the cylinder wall to a high position and then fall down. After being divided into multiple material streams by the V-shaped structure, they converge at the bottom of the cylinder. At the same time, the material moves and slides along the cylinder wall, and the particles form shear forces to disperse the agglomerates. After continuous diffusion, an overall uniform mixing is achieved, and high uniformity mixing operations can be completed within a short period of time.

Product features

1. Excellent mixing effect: The V-shaped structure has no material retention dead corners, which can effectively disperse dry powder agglomerations, achieve high mixing uniformity, and complete the mixing process faster than conical and other mixing machines.

2. Protecting the materials and saving materials: Without complex stirring components, it will not crush or pulverize the materials, is suitable for sensitive powders such as those that are brittle or prone to moisture absorption, and the discharge is thorough, with the residual material amount being much lower than that of screw-type mixing machines.

3. Easy to clean and compliant: The inner wall is smooth without material retention dead corners, and it can be designed as a quick-disassembly or mirror-polished style, complying with food and pharmaceutical grade standards. The cleaning difficulty is much lower than that of paddle-type mixing machines.

4. Low consumption and durable: There are no high-speed sealing components, the operation noise is low, mechanical wear is small, faults are few, and daily maintenance only requires the lubrication of bearings. The long-term maintenance cost is lower than that of screw-type mixing machines.

Product Parameters

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Details Lmages

Product Shows

Packing & Delivery

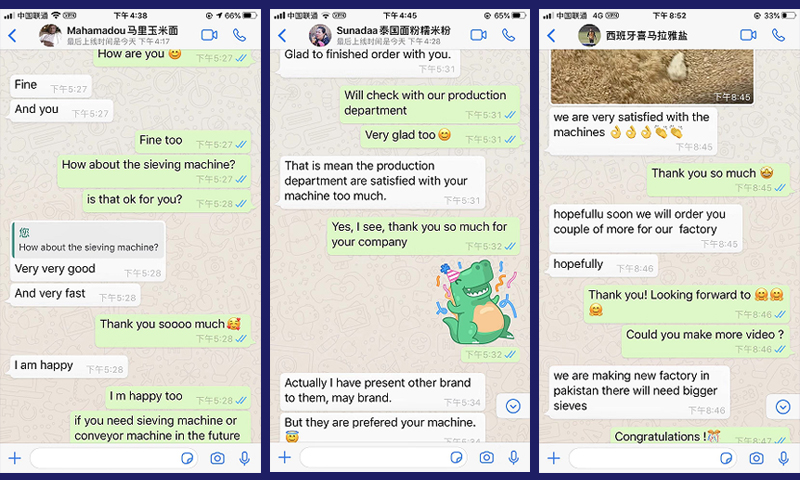

Why Choose Us

About us

Company Profile

|

|

V Type Powder Mixer with 50L-5000L Capacity for High Mixing Uniformity and No Dead Corners in Pharmaceutical and Chemical Industries Images |